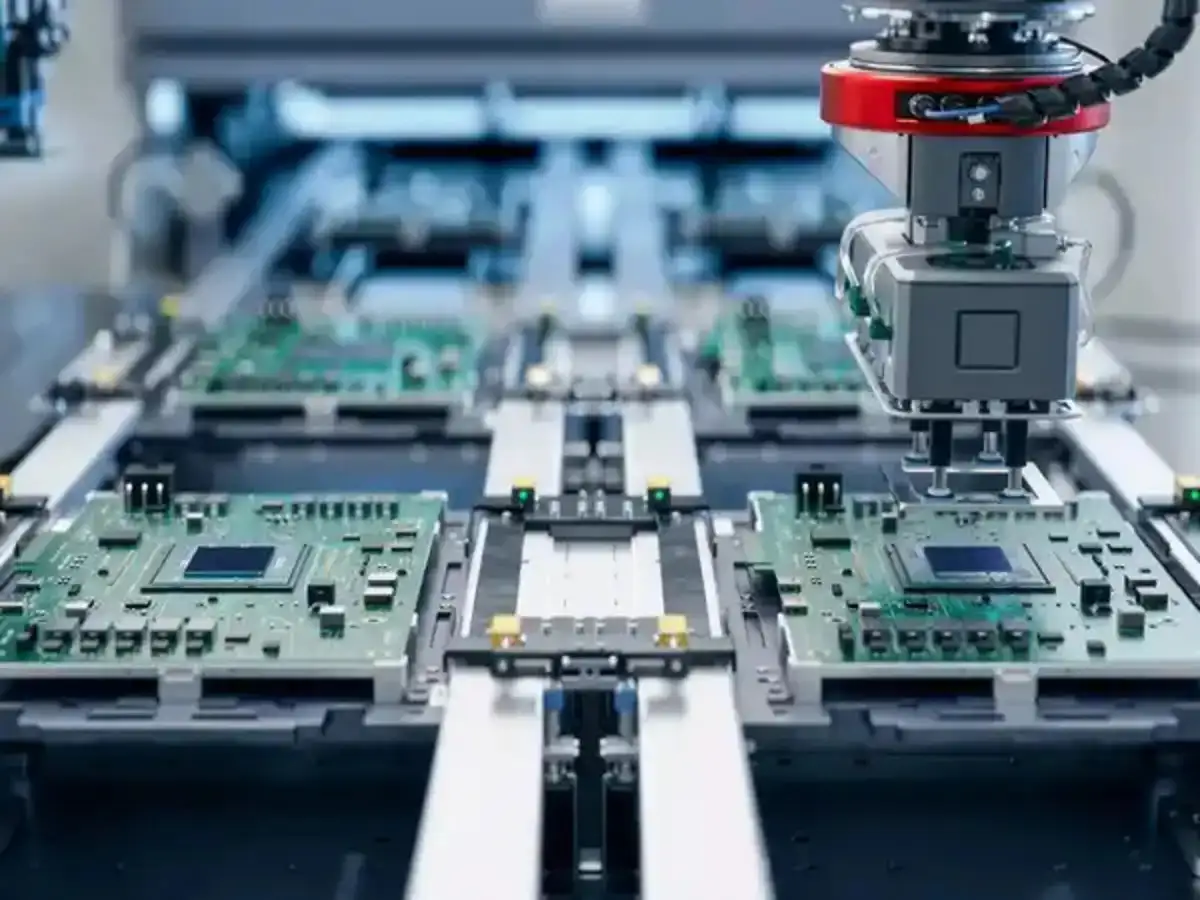

A landmark sustainable electronics manufacturing facility is taking shape in Sehore district, Madhya Pradesh, marking one of the country’s most significant climate‑oriented industrial investments. The project — backed by an integrated architectural strategy prioritising energy efficiency, low carbon intensity and worker welfare — promises to redefine how high‑tech production sits within broader urban and regional ecosystems. The emerging printed circuit board (PCB) factory, designed by an architecture practice with a track record in environmentally responsible buildings, is set to become a major node in India’s electronics value chain. PCBs are essential substrates in nearly all modern electronics — from consumer devices to renewable energy systems — and boosting domestic manufacturing aligns with national efforts to reduce import dependence while creating skilled jobs.

Industry analysis suggests India’s PCB output could scale to about ₹1,200 billion (US $14 billion) by 2030, driven by rising local demand and global supply chain diversification. A facility of this scale is anticipated to play a strategic role in that growth, shortening supply chains and enhancing resilience for local manufacturers. Senior officials involved in industrial planning highlight that the project contributes to equitable economic expansion beyond major metropolitan clusters, fostering manufacturing capacity in central India and expanding employment opportunities across skill levels. Urban planners note that when industrial facilities incorporate sustainable design — including passive climate control, responsible water use and worker‑centred amenities — they can strengthen links between industrial estates and surrounding communities.

For Madhya Pradesh, this initiative dovetails with broader state strategies to attract high‑value technology investment. Government sources report approvals under central schemes aimed at bolstering electronics and component manufacturing have already unlocked several multi‑hundred crore projects in the state. These are expected to generate thousands of direct jobs and a multiplier effect in ancillary services. Urban and economic development researchers point out that factory design matters for more than production capacity. Facilities that integrate natural ventilation, daylighting and material reuse can reduce operational carbon and set benchmarks for industrial sustainability. Such approaches also support healthier work environments, lowering stress and absenteeism, and signalling that industry can be a partner in resilient city building rather than a mere land‑use neighbour.

The plant’s footprint is also being framed in the context of the transition to greener industry. As India ramps up renewable electricity and clean manufacturing incentives, projects like this PCB facility demonstrate how industrial growth can coincide with climate goals and community welfare. For nearby municipalities, integrating this industrial anchor with infrastructure — from housing and transit to skills training — will be critical. Experts argue that long‑term success hinges on ensuring that the investment supports local supply chains, mitigates environmental impacts and contributes to inclusive, future‑ready urban regions.

Also Read: Mira Bhayandar Plans Pet Friendly Urban Space

Madhya Pradesh New Green PCB Hub Signals Urban Industrial Shift