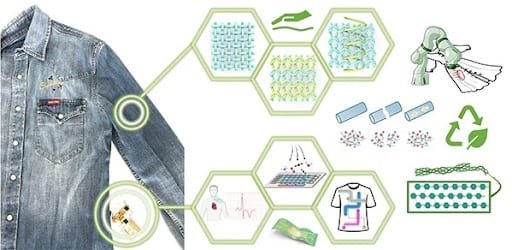

Electronic textiles (e-textiles) are evolving towards a sustainable and scalable

future through adoption of innovative wearable e-textiles aligned with the

principles of the 4R design concept: repair, recycle, replace, and reduce.

E-textiles, worn close to the skin, find applications in healthcare, gaming,

athletics, and environmental monitoring, thanks to embedded electronic

components that enable energy storage, sensing, display, actuation, and

computation.

While the potential of e-textiles is vast, there are two critical challenges to their

widespread adoption and environmental sustainability. First, high costs hinder

consumer adoption, and second, mass production of e-textiles poses

environmental concerns, particularly microplastic water pollution.

To prevent e-textiles from becoming the next environmental problem, an

international team of engineers and scientists from the UK, Canada, the US, and

China, led by the University of Cambridge, proposes the 4R e-textile design

concept. In a study published in the journal Nature Materials, the research team

introduces the 4R design concept, which encompasses repair, recycle, replace,

and reduce as key principles. It calls for innovative materials selection and

biofabrication-inspired processing methods. Biofabrication leverages additive

manufacturing processes to produce biomaterials, devices, cells, and tissues.

This approach aims to achieve sustainable growth while balancing economic

returns and scalable commercialisation with environmental consciousness,

aligning with consumers’ growing focus on sustainability in their purchasing

choices.

The team raises concerns about the e-textile supply chain and its potential

environmental burden, exacerbated by the increasing use of nanomaterials in e-

textiles.