The Bangalore Water Supply and Sewerage Board (BWSSB) is breaking new ground—literally—by employing microtunnelling techniques to expand its pipeline network in Bengaluru. This innovative method aims to tackle the city’s unique infrastructural challenges, including water bodies and rocky terrains, without disrupting daily life. As the state government considers building tunnel roads to alleviate traffic congestion, the BWSSB’s foray into tunnelling marks a significant step forward in urban infrastructure development.

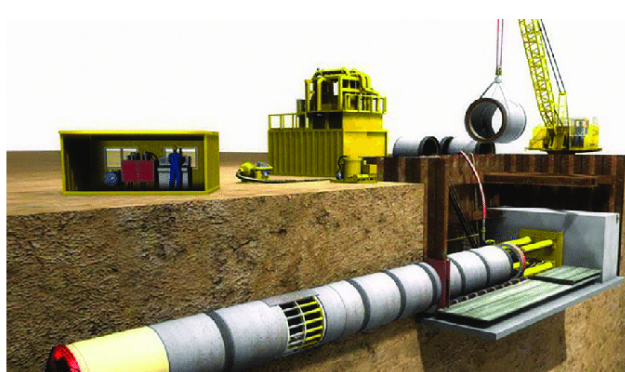

Traditionally, the installation of water and sewer pipelines has involved open excavation or horizontal drilling. However, these conventional methods are impractical in densely populated areas or regions with complex landscapes. To address these challenges, BWSSB has introduced microtunnelling machines, a first for the organisation. Unlike the large tunnel boring machines (TBMs) used by Bangalore Metropolitan Rail Corporation Limited (BMRCL) for Metro tunnels, BWSSB’s microtunnelling machines, imported from China, are smaller and more precise, with a diameter of 1.2 metres compared to BMRCL’s 3.3 metres.

The initial deployment of this technology is underway at Kaikondrahalli Lake along Sarjapur Road in southeast Bengaluru. According to BWSSB’s chairperson, this method is particularly beneficial in critical areas where traditional excavation is impossible. The machines are capable of burrowing six to seven metres per day at a depth of six metres from the ground. As they tunnel, the excavated area is sealed with concrete structures, creating a secure passage for pipeline installation. The BWSSB plans to construct 450 metres of tunnel across various city locations, with significant progress already made at Kaikondrahalli Lake. Engineers have completed 32 metres of tunnelling and are currently working on an additional 120 metres. Similar projects are slated for 8 to 10 other locations across Bengaluru, with Larsen & Toubro (L&T) engineers collaborating on the initiative.

Although microtunnelling is five times more expensive than traditional methods, the benefits outweigh the costs, particularly in avoiding disruption to surface-level activities. Before commencing any work, engineers conduct thorough landscape studies using radiography tests and sonar technology. This analysis provides critical information about rock layers, types, and extent, allowing for precise planning and alignment. The goal is to ensure the natural flow of water or sewage, even when tunnelling under water bodies. BWSSB’s adoption of microtunnelling signifies a forward-thinking approach to urban infrastructure, setting a new standard for other Indian cities grappling with similar challenges. The project underscores the city’s commitment to sustainable development and technological innovation.